The U.S.’s billowing trade policies rattled global markets this week with the onset of new tariffs that were then mostly paused. Although the uncertainty took a bite out of Big Pharma stocks, the industry was mostly spared from the worst of the upheaval.

“The Trump administration’s North American, universal and China-targeted tariffs had limited direct impact on pharma due to exemptions for active pharmaceutical ingredients so far,” said Zara Muradali, head of life sciences and tax principal at Grant Thornton Advisors.

Still, a deepening trade row has fueled speculation over whether it would incentivize pharma to buck a long-held reluctance to manufacture in the U.S. Although tariffs alone are unlikely to offset the high cost barriers that remain for U.S. drug production, pharma could rethink its supply chain as the rubber hits the road on other policies, Muradali said.

“Factors influencing this shift include the U.S. government emphasizing reduced reliance on foreign suppliers; major pharmaceutical companies making … U.S. expansions; and policy incentives with the Inflation Reduction Act and CHIPS and Science Act, which include provisions for advanced manufacturing … through tax credits and R&D funding,” Muradali said.

The U.S. is capable of handling a manufacturing burden, though, as demonstrated by the rapid scale-up and production of COVID-19 vaccines just a few years ago.

“Another example in generics and non-patented drugs would be Civica Rx, a nonprofit generic manufacturer that raised $125 million to produce essential generics, addressing shortages and price volatility,” Muradali pointed out.

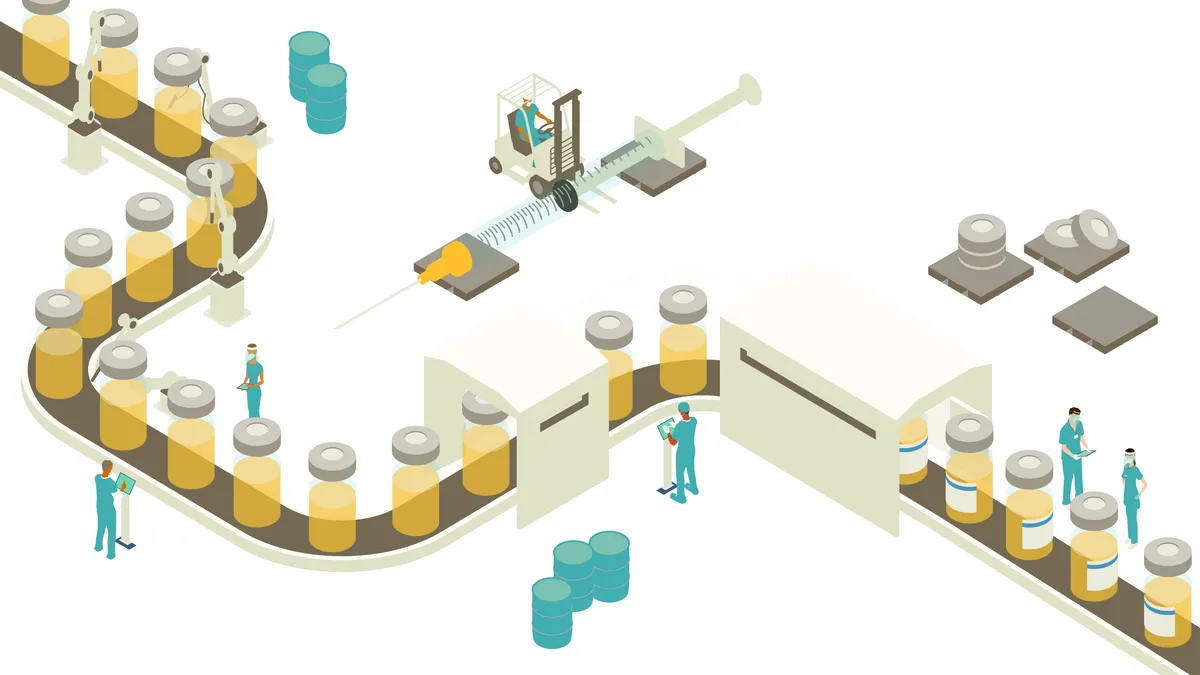

A slew of technological advances such as continuous manufacturing, AI-enabled processes, robotics and automation have brought labor costs down, and regulators are offering more support.

“The FDA’s Emerging Technology Program fast-tracks approvals for innovative production methods, cutting regulatory timelines,” Muradali said. “Also, the FDA’s Advanced Manufacturing Center promotes agile approvals for technologies like 3D-printed drugs.”

While some pharma companies are turning to contract manufacturers to help expand their U.S. footprint as the trade battles play out, others are likely to “wait and see,” Muradali said.

Regardless of where the Trump administration lands on tariff policies, several large pharmas are already in the midst of U.S. capacity expansions to meet rising demand for key products.

Novartis became the latest company to make a major manufacturing move this week when it revealed plans to pump $23 billion into building or expanding capacity at 10 sites in the U.S.

Here’s a look at some of the other large manufacturing investments pharma companies have revealed in recent months.

Eli Lilly goes big in the U.S.

Few companies are pumping as much cash into U.S. manufacturing as Eli Lilly.

After a string of production investments, the company said in February that it plans to expand American capacity once again — bringing its five-year U.S. manufacturing spend to $50 billion dollars.

Lilly will use the new capital investments to build four production sites in the U.S., including facilities that make active pharmaceutical ingredients and injectable drugs, while creating up to 10,000 construction jobs and 3,000 permanent roles for high-skilled workers, the company said.

While Lilly’s quest to crank out more drugs has benefited from sales of its weight loss and diabetes medications, the company said it’s optimistic about the potential of oncology, immunology and neuroscience pipelines, as well.

Lilly’s also looking at ways to refine the manufacturing process. The company recently teamed up with Merck & Co. and Purdue University to launch a consortium that will research and develop new manufacturing technologies.

Novo’s production push

Amid skyrocketing demand and sporadic shortages for its blockbuster diabetes and weight loss medications, Novo Nordisk has also shelled out billions to expand its global manufacturing footprint in recent years.

Most recently, the company announced a $1 billion upgrade to a facility in Brazil that makes injectable drugs, including GLP-1s like Ozempic. The investment marks one of the heftiest ever seen by the pharma manufacturing industry in the country.

In the U.S., the Danish pharma’s splashiest — and most controversial — deal was its $16.5 billion acquisition of Catalent, a contract manufacturing firm previously aligned with many of Novo’s rivals. Although the matchup was met with some industry resistance amid concerns it could hamper Catalent’s other contracts, it was ultimately finalized in December.

Novo also funneled $4.1 billion into building a second fill-finish facility in North Carolina and made similar investments around the world last year, including production expansions in Denmark and a $200 million deal to purchase a Novavax plant in the Czech Republic.

The company plans to keep the spending spree going in 2025. Novo said in an annual report that it will invest about $9 billion throughout the year to shore up its capacity and supply chain network.

Amgen and J&J’s moves in North Carolina

Amgen is expanding its production prowess in North Carolina, the company announced in December. The $1 billion investment will establish a new drug substance facility and create 370 new jobs, Amgen said.

Amgen’s earnings rose by 13% in the third quarter of last year thanks to increasing sales for osteoporosis and cholesterol meds, beating analyst expectations.

The new production investment builds on a previous $550 million commitment the company made at its Holy Springs campus in the state, and is one of several pharma-backed capital infusions recently announced in North Carolina, which boasts over 100 pharma manufacturing sites.

J&J is shelling out in the notorious biotech innovation state with a $2 billion plan to build a biologics manufacturing site in Wilson, the company said in October.

The new facility, which will help ensure “a resilient supply chain,” will produce oncology, immunology and neuroscience drugs and staff 420 workers, the company said.