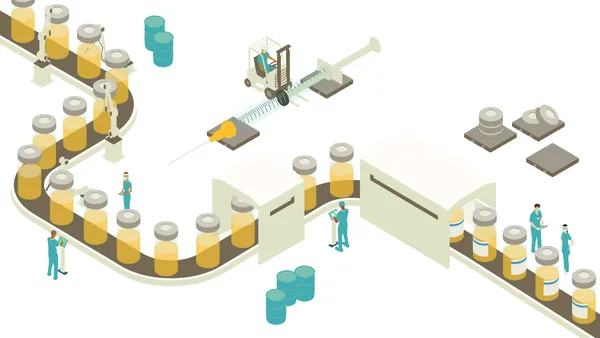

Pharmaceutical companies are now testing the use of radio frequency identification (RFID) technologies, which hold the potential for protecting the patient, protecting the brand, and strengthening the supply chain. New applications of a not-so-new technology are about to completely change how the pharmaceutical supply chain is managed. Radio frequency identification (RFID) technologies will give current track-and-trace methods a powerful boost and lead to a wireless supply chain system that is more efficient and effective. RFID involves the placement of small electromagnetic chips on cartons, pallets, and individual product labels. This allows manufacturers and wholesalers to track products more closely than ever before as they move throughout the distribution process. RFID is fairly new in the pharmaceutical industry, but it is not a new technology. Toll booths (E-ZPass) and gas stations (Mobil’s Speedpass) have been using this technology for some time. Consumer packaged goods manufacturers are responding to a mandate issued by Wal-Mart, which requires the retailer’s largest 100 suppliers, as well as manufacturers of Schedule II drugs, to ship RFID-labeled pallets and cases to some of its distribution centers. The RFID market across all industries for related consulting, implementation, and managed services is expected to reach $2 billion worldwide by 2008, according to a report from IDC in December 2004. The FDA is taking a serious look at RFID technology and has proposed that drug makers adopt electronic track-and-trace technology, including RFID, by 2007. Some pharmaceutical companies have started pilot programs or are planning pilots for some products enabled with RFID tags. This is being driven by several factors, including the push by some state governments — Florida, Nevada, and California — to require drug “pedigrees,” which include transaction information as a way to trace a drug from the point of origin to the point of dispensing to guard against counterfeit drugs from entering the distribution chain. Although the states do not require an electronic pedigree, industry experts say RFID would be a more efficient and effective way to meet the regulations. Drug counterfeiting is estimated to cost the worldwide pharmaceutical industry $30 billion annually, according to a study by ABI Research. “There’s been an acceleration of counterfeit drugs coming into the pharmacies around the country, which threatens patient safety, and that is not something we can tolerate in our society,” says Aaron Graham, VP and chief security officer at Purdue Pharma L.P. The biggest opportunity that RFID offers is the ability to address supply-chain visibility, says Christopher Holt, VP of healthcare at UPS Supply Chain Solutions Consulting Services. “There are large black holes in every pharmaceutical company’s supply chain,” Mr. Holt says. “If a company knows where its products are at all times, then it can make better decisions about what to ship where, which can greatly improve customer service, lower distribution costs, and achieve regulatory compliance.” R. T. (Terry) Hisey, VP and life science industry leader at Capgemini, says RFID can help control the integrity of the drug-supply pipeline from point of finished goods production to point of dispensing. “RFID can ensure control of the product from a safety standpoint, ensuring the accuracy and the validity of the shipping information,” he says. “This technology will clearly put a big dent in the introduction of a counterfeit product and also help with drug safety by absolutely identifying products and reducing the number of medication errors, as well as ensuring the integrity of the drug-supply chain.” But making this work will be the hard part, Mr. Holt says. “The software and hardware to manage this information and get it into a usable fashion that is proprietary, but that can be shared with some trading partners and not with others, is a massive IT challenge,” he says. “I think people have their heads in the sand about how much technology is needed to make these data useful.” RFID in Pharma Many pharmaceutical companies are conducting or considering RFID pilots programs. Pfizer Inc., for example, in November 2004 announced that it plans to place RFID tags on all bottles of Viagra intended for sale in the United States by the end of this year. The company will add passive RFID tags to cases and retail packages of Viagra at an estimated initial cost of several million dollars. GlaxoSmithKline also announced in November 2004 that it intends to begin using RFID tags in the next year to 18 months on at least one product deemed susceptible to counterfeiting. In its consumer healthcare division, GlaxoSmithKline put RFID tags on all pallets shipped to a central distribution center for Metro, a German retailer, and it tags pallets and cases to Wal-Mart’s Texas distribution centers. In R&D, GlaxoSmithKline uses RFID to track and verify patient packs before distribution and to simplify critical business processes. In November 2004, Purdue Pharma announced a pilot program to integrate RFID tags on labels for 100-tablet bottles of OxyContin shipped to two of its largest customers. Mr. Graham says the company’s new bottles have a feature that shifts from green to blue to purple. “We also have RFID tags, which allow us to track the product from our manufacturing line through our vault through our back door all the way to the pharmacy,” Mr. Graham says. “This is consistent with the comprehensive strategy that the FDA has recommended.” The RFID-tagged bottles of OxyContin are being sent to Wal-Mart and H.D. Smith, the seventh-largest drug wholesaler in the United States. Mr. Graham says for retailers that have the technology, they are shipping fully tagged products of both OxyContin and Palladone. Purdue is using technology provided by Symbol Technologies Inc., formerly Matrics; specifically Purdue is using Symbol MC9000-G, which combines RFID capabilities, bar-code reading, imaging, and WiFi connectivity into a mobile computer. According to Liz Churchill, director of industry solutions, life sciences, at Symbol, the RFID inlay is part of the OxyContin label and is applied on the bottling or packaging line. Mr. Graham says Purdue has invested about $2 million to set up the infrastructure internally, and it costs between 30 cents and 50 cents a tag per bottle. “We didn’t do a traditional ROI calculation,” Mr. Graham says. “We determined this is the cost of being a good corporate citizen and protecting our patients. Our management said patient safety is the ROI.” Pharmaceutical suppliers also are implementing RFID solutions. One is West Pharmaceutical Services Inc., which supplies overseals, the aluminum and plastic seals that hold stoppers on the vials for injectable drug products. “There are a couple of strong benefits for putting the tag on the seal,” says Don McMillan, VP of marketing, Americas, at West Pharmaceutical Services. “One is that, by design, our seal is tamper evident, so at the point of use, when the plastic piece is torn off, the tag also is torn. This means that the packaging can’t be reused for packaging of other drugs and labeled to make them appear genuine.” IBM Business Consulting Services is about to begin a six-month pilot program of RFID technologies with five companies, including two pharmaceutical manufacturers, one distributor, one retailer, and one hospital. Some of these companies will do proof-of-concept and pilot programs around item-level tagging, says Janice Chiu-Kikta, partner, life-sciences practice at IBM Business Consulting Services. “Generally, pharmaceutical products are broken down very quickly from the pallet and case level to the individual items,” she says. “The quicker the case is broken down, the less value there is to having tags on a pallet or a case in terms of a product authenticity perspective.” The Pedigree Mandate Ms. Chiu-Kikta says a key driver for the implementation of RFID has been the efforts by several states for drug “pedigrees,” basically a feasibility chain that helps track drug shipments from the manufacturer to the patient. Two states — Florida and California — are leading the way in this area. In Florida, as of July 2003, if a prescription drug is on a specified drug list of 31 drugs that are deemed most likely to be counterfeited, then a wholesaler must comply with the pedigree paper requirements. State officials say an electronic document can be submitted. Effective July 1, 2006, wholesale distributions of all prescription drugs will be subject to the pedigree requirements. In California, all shipments will be required to have pedigrees beginning Jan. 1, 2006. The primary focus of these measures is to guard against counterfeit drug products entering the distribution chain. While drug counterfeiting is not widespread within the U.S. manufacturing and distributing pharmaceutical systems, the FDA is investigating more of these cases. Counterfeit drug investigations by the FDA have increased to more than 20 per year since 2000, after averaging only five per year through the late 1990s. “The pedigree would include general product information for that pharmaceutical product: the name of manufacturer, lot number, expiration date, container size, strength, etc., as well as transaction details in terms of who the product was sold to and the invoice number,” Ms. Chiu-Kikta says. The National Association of Boards of Pharmacy (NABP) established a task force to explore the feasibility of creating and maintaining a clearinghouse for relevant information to establish an electronic pedigree. The task force will work with EPCglobal Inc., a standards organization, to create the necessary standards for the development of e-pedigree software, as well as explore ways to establish an accreditation program for e-pedigree software platforms. Until there are standards, RFID systems won’t be compatible, says Michael Webster, director of life sciences at Ross Systems Inc. “There isn’t interoperability between all RFID systems,” he says. “Wal-Mart is leading the way because it is choosing a particular technology and telling its partners which RFID format to use and how the information should be encoded on the tag.” Benefits of RFID RFID tagging can overcome some of the challenges with bar codes, industry leaders say. “The problem with bar-code data collection is that it requires individuals to get close to the label in order to scan it,” Mr. Webster says. “Sometimes the receiving locations may not have the same type of format for bar coding so they can’t read the label or there might be a pallet with multiple product labels on them.” Using RFID, there is a trail of information that can be traced that can’t be done with bar codes, says Sujeet Chand, chief technology officer at Rockwell Automation Inc. “Bar codes have information embedded inside them, and when they are read, it is the same information over and over,” he says. “With RFID, we can go back and trace when the drug was made, who made it, what ingredients went into the drug, and what were the processing conditions when that drug was made. All of that information is keyed to that single tag, and that’s what makes RFID powerful.” Ms. Chiu-Kikta says with RFID technology it isn’t necessary to have line of sight to read the tags. “With bar codes, every case would have to be opened and the bar codes scanned individually, whereas with RFID a tunnel reader can handle the entire case,” she says. “For situations where there are mixed cases (different products in the same case), item level authentication is more important. “We saw a demo for a tunnel reader for high frequency tags,” she continues. “There were two cases with 100 items in each, and it took the reader five seconds to read all of the labels.” The advantage of RFID is that the technology offers the ability to move toward mass serialization of the drug supply chain to help avoid counterfeit products, as well as to reduce medication errors, Mr. Hisey says. “Companies should think of RFID as an enabling technology, not simply a product technology,” he says. “RFID is a management tool for improving research and development, clinical-trial management, and other processes where improved asset and process management accuracy would deliver value. Instead of thinking of RFID as a cost, companies should think about the other processes in all other areas of the business that could benefit from improved management accuracy and reduced errors.” “RFID can eliminate the risk and hassles a company faces with regulatory compliance,” says Surajiet Khanna, director, process engineering and quality at Intrasphere Technologies Inc. “For example, the FDA has become very rigid on labeling. For label control, RFID works tremendously well because the tag itself offers information about the composition, when it was made, and the expiration date.” Todd Skrinar, partner in the healthcare and life-sciences practice at Unisys Corp., says the most common way of measuring ROI is in terms of the organization. “ROI can be found both inside and outside the four walls of an organization,” he says. “RFID can drive significant ROI for wholesale distributors through improved product tracking by deterring threats such as counterfeiting, and RFID contributes to improved patient safety and helps protect the brand.” Mr. Skrinar says RFID can drive operational efficiency. “Longer term, as incentives are aligned with downstream supply-chain partners, RFID capabilities can free up working capital by allowing the extended supply chain to operate at high-service levels with less inventory,” he says. Ms. Chiu-Kikta says another benefit of RFID is the ability to track chargebacks and reduce the effort by both manufacturers and distributors to determine what the chargeback should be. This, she says, will take some time, requiring widespread adoption of RFID among the different supply-chain parties. Retailers and Wholesalers Wal-Mart initially announced its EPC initiative in June 2003. The company began the first phase of implementation with its top 100 suppliers tagging cases and pallets of products headed to three Dallas/Fort Worth area distribution centers by January 2005. The effort is now being expanded throughout North Texas and South Central Oklahoma. Specifically, EPCs will be used in 90 Wal-Mart stores and 31 Sam’s Club locations in Texas, as well as 16 Wal-Mart stores and five Sam’s Club locations in Oklahoma. Ms. Chiu-Kikta says there has been a lot of visibility around the Wal-Mart mandate, which has requested its suppliers use the 9.15-megahertz frequency. This is adequate for tagging boxes and pallets, but may not work for industries that are considering using RFID at the item level. “Based on the type of electronic magnetic properties of those different frequencies, it’s been found that the 13.56 signal is not as susceptible to being altered by water and metal as the ultra-high, 9.15 frequency,” she says. Technology and Cost Hiccups One of the challenges of this technology, however, is the failure of the tags or the failure of the readers. “I’ve heard that in some instances, there’s a 25% to 35% failure rate of RFID tags on regular labels,” Mr. McMillan says. “In the pharmaceutical supply chain, labels are reconciled one to one, and a failure there could mean someone’s life is at risk.” Mr. Chand says sometimes the connections are not established, a chip is missing, or the antenna is not connected. “So, bottom line, for this technology to be widely adopted, the yield rate of the tags has to improve,” he says. “With the new standard, the yield rates are expected to increase to 90% or 95%.” According t Ms. Churchill, the failure rate is often overstated, and as product is ramped up to hundreds of millions of tags in the next 12 months to 18 months, the failure rate will drop dramatically because of the scale of production. Experts say another challenge to RFID technology is cost. “There are reports that tags cost five cents or 10 cents a piece,” Mr. McMillan says. “But that’s when the quantity is in the millions. No one company is buying them in these quantities at this point, except for maybe a few consumer goods companies that supply to Wal-Mart. When purchasing 10,000 tags for a pilot study, they can be more than $1 a piece. But there is no doubt that the cost of these tags will come down dramatically over time.” PharmaVOICE welcomes comments about this article. E-mail us at [email protected]. Aaron Graham I encourage all companies to get on board with RFID. We all share a common enemy: criminals engaged in counterfeiting drugs, which puts patients at risk. Together we can make an impact. RFID technologies Liz Churchill The problem with bar codes is that they don’t provide the benefit of being able to be read an entire case of product at one time. Don McMillan We’re going to see rapid advancements with RFID technology and its capabilities, as well as a reduction in costs. The Case for RFID The use of radio frequency identification (RFID) by pharmaceutical companies will be limited to a “track-and-trace” role until electronic product code (EPC) specifications are revised, which could take up to two years, according to a study by Meta Group. Once implemented, Meta Group predicts that RFID will prove extremely beneficial to the pharmaceutical industry, offering ROI in the following five key areas: Inventory Management: RFID technology can merge identity with environmental information to create an individualized expiration date based on the environment’s effects on the active ingredients. Recalls: In the event that a product recall is initiated, pharmaceutical organizations would be able to respond more efficiently and quickly in identifying the recalled product. Patient Safety: By combining RFID-tagged drugs with other positive identification measures, the FDA estimates that most of the 1.25 million adverse reactions and 7,000 patient deaths annually in the United States due to drug errors could be prevented. Product Diversion: Positively identifying shipments and tracking them to their intended destinations could significantly reduce the size of the “gray market.” Counterfeiting: Current recommendations are to deploy two forms of anti-counterfeiting measures — one visible (i.e., holograms) and one invisible (i.e., RFID tags) — to implement formidable obstacles to counterfeiting. Source: Meta Group, Stamford, Conn. For more information, visit metagroup.com. Surajiet Khanna RFID reduces risks and that is what we all care about in terms of human health. RFID can address product tracking, as well as contain information about every particular element about a particular product. Todd Skrinar With the evolving regulatory environment, compliance agendas seem to be driving most of the investment in RFID. Priorities may differ based on the function, but manufacturers are certainly focused on the FDA’s direction. Sound Bites from the Field PharmaVoice asked industry experts to speak to the advantages of the use of RFID technology in the pharma industry. Ilisa Bernstein, Pharm.d., J.D., is Senior Advisor for Regulatory Policy, Food and Drug Administration, Washington, D.C., which is responsible for protecting the public health by assuring the safety, efficacy, and security of human and veterinary drugs, biological products, medical devices, the nation’s food supply, cosmetics, and products that emit radiation. For more information, visit fda.gov. “We put out the policy guideline because the FDA wants to do what it can to facilitate the implementation of RFID into the drug supply chain. The issues addressed in the compliance policy guide respond to some of the questions that the industry had raised to date. In the counterfeit report issued in February 2004, we talked about the benefits of electronic track and trace, with RFID being one mechanism. This is the mode that seems the most promising and where most efforts are being put toward.” Jeff Richards is CEO of R4 Global Solutions, San Francisco, which enables businesses to gain real-time visibility, control, and information through the effective evaluation, implementation, integration, and support of RFID and RFID-related technologies. “The principle advantages of RFID center around serialization capability and nonline sight scanning. Serialization enables the identification of each unique unit versus the product category with bar codes. This serialization capability (along with the requisite software and data exchange capability) is applicable to the pharmaceutical industry in that it will enable: item-level track-and-trace and pedigree information; lot expiration tracking; anticounterfeiting; and increased inventory visibility. Nonline sight-scanning functionality can significantly reduce the time required to scan pallets and cases of items throughout the supply chain. Door “portals” configured with RFID readers and antennae can automatically detect when product is moving from a stock room to a store floor, for example, and update the inventory systems accordingly.” Joseph A. Slota is Director and RFID Life Sciences Lead, Deloitte Consulting LLP, New York, a professional services firm that provides audit, tax, financial advisory services, and consulting. For more information, visit deloitte.com. “People talk about RFID from a defensive perspective. I think it should be seen more from an offensive perspective. RFID can be used to create new opportunities in the marketplace that will embellish upon the shareholders’ wealth. If companies have the ability to use RFID to data mine based on the information that RFID puts out, that data mining would be able to make their relationships stronger. That kind of opportunity can reshape the whole value chain for life-sciences companies because they will be able to use information to connect, to create, and to establish facts that aren’t available today.” Janice Chiu-Kikta Pharmaceutical companies should start to do pilot programs with RFID technology, even if they are simple ones. It is in their best interest to take some baby steps because a lot of learning can be gained. Michael Webster My advice for the pharma industry would be to step carefully and to make sure that trading partners are in line with the technology that is being bought. Sujeet Chand RFID can be very powerful. We are urging our customers to think about RFID more broadly as opposed to just applying it to a single case or pallet and pushing it out to Wal-Mart. Experts on this topic Sujeet Chand. Chief Technology Officer, Rockwell Automation Inc., Milwaukee; Rockwell Automation is a global provider of industrial automation power, control, and information solutions that help customers meet their manufacturing productivity objectives. For more information, visit rockwellautomation.com. Janice Chiu-Kikta. Partner, Life Sciences Practice, IBM Business Consulting Services, Irvine, Calif.; IBM Business Consulting Services provides business process and industry expertise and the ability to translate that expertise into integrated, adaptive, on-demand business solutions. For more information, visit ibm.com/services/bcs. Liz Churchill. Director, Industry Solutions-Life Sciences, Symbol Technologies Inc., Rockville, Md.; Symbol Technologies offers products and solutions that capture, move, and manage information in real time to and from the point of business activity. For more information, visit symbol.com. Aaron Graham. VP and Chief Security Officer, Purdue Pharma L.P., Stamford, Conn.; Purdue is engaged in the research, development, production, and distribution of both prescription and over-the-counter medicines and hospital products. For more information, visit purduepharma.com. R. T. (Terry) Hisey. VP and Life Science Industry Leader, North American Consulting Services, and Global Life Science Supply Chain Leader, Capgemini, New York; Capgemini is a provider of consulting, technology, and outsourcing services. For more information, visit us.capgemini.com. Christopher Holt. VP, Healthcare, UPS Supply Chain Solutions Consulting Services, Alpharetta, Ga.; UPS Supply Chain Solutions has resources to manage every aspect of global supply chains, from transportation management to logistics and distribution to customs brokerage and international trade services. For more information, visit ups-scs.com. Surajiet Khanna. Director, Process Engineering and Quality, Intrasphere Technologies Inc., New York; Intrasphere Technologies is a technology consulting firm with a core focus on life sciences. For more information, visit intrasphere.com. Don McMillan. VP of Marketing, Americas, West Pharmaceutical Services Inc., Lionville, Pa.; West Pharmaceutical Services is a manufacturer of components and systems for injectable drug delivery, including stoppers and seals for vials and closures and disposable components used in syringe, intravenous, and blood- collection systems. For more information, visit westpharma.com. Todd Skrinar. Partner in the Healthcare and Life Sciences Practice, Unisys Corp., Blue Bell, Pa.; Unisys is a worldwide information technology services and solutions company. For more information, visit unisys.com. Michael Webster. Director of Life Sciences, Ross Systems Inc., Atlanta; Ross Systems offers Internet-architect solutions in a comprehensive, modular suite that spans the enterprise, from manufacturing, financials, and supply-chain management to customer relationship management, performance management, and regulatory compliance. For more information, visit rossinc.com.

An article from

From Bar Codes to Chips & Antennas

Filed Under:

Manufacturing