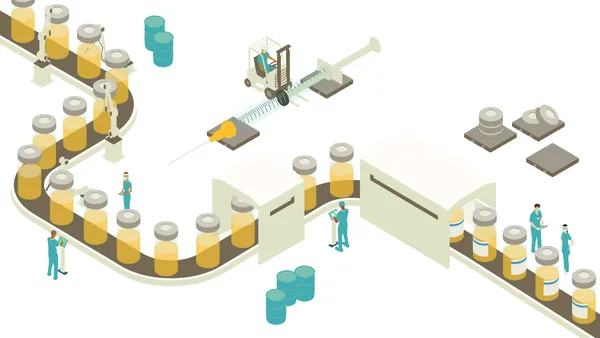

Supply Chain Szwast. Pharmaceutical manufacturers face the challenges of accelerating new product introductions, shifts in global sourcing and distribution, the intensifying need for companies to meet regulatory and customer compliance rules, and enhancing shareholder value. Product introductions are a challenge because new products are frequently a poor fit within a pharmaceutical company’s traditional supply chain. They tend to require a more responsive scalable conduit to reach the market, and this can be problematic for a legacy supply chain that reflects a company’s history rather than aligning to a new strategy. This also is true of more established products as they transition from prescription to over-the-counter. This change in channel distribution has logistics requirements similar to a new product launch. The ongoing globalization of the pharmaceutical industry also brings inherent challenges. Today, pharmaceuticals are produced in diverse locations that previously have not been thought of as manufacturing epicenters. A finished product can easily have different production phases that happen in different countries or in some cases continents. How companies effectively and efficiently source products from these disparate locations without loss, delay, or diversion is a key area of competitive differentiation and indeed profitability. It is not enough to source and distribute pharmaceuticals quickly; the tasks must also be done precisely. While meeting regulatory compliance (FDA, DEA, individual state pharmaceutical licensing regulations) has long been a core competency of successful pharmaceutical corporations, being compliant is a constantly moving and evolving target that requires continuous process improvement. Further, the ongoing migration of many products into the retail-sales channel drives the need for customer compliance in addition to adherence to regulatory requirements such as voluntary intra-industry compliance standards. The ability to meet the aforementioned challenges is a key demarcation between leaders and laggards in this industry. graham. From my perspective, having worked for the FDA, DEA, and Pfizer before joining Purdue Pharma, the counterfeiting of prescription drugs is a growing patient-safety issue. New technology is now available that can help ensure the integrity of the pharmaceutical supply chain by tracking medicines electronically from production plant to pharmacy through the inclusion of RFID (radio frequency identification) “license plates” on each bottle. The FDA is encouraging all companies to incorporate this technology by 2007. Purdue began using this technology in November 2004 when it launched the industry’s first integrated, anticounterfeiting, track-and-trace packaging for a scheduled pharmaceutical product. Each 100-tablet bottle of OxyContin Tablets provided to two of our largest wholesale customers now includes a RFID tag that can be scanned by special sensors. This will make it possible for our products to be tracked and validated along every step of the supply chain. We also are adding a special variable-effect, color-shifting ink to our labels to thwart would-be counterfeiters. We expect this to become the industry standard in a few years. In a global market, trade compliance becomes every bit as important as regulatory compliance. The ability to cross borders with precision and speed are keys to being successful in the international marketplace. Aaron Graham Purdue Pharma L.P. What’s Your Opinion? 2005 — A look ahead What are the most significant business challenges you believe the industry will face in 2005? Higher development costs and deceleration of drugs to market I believe technologies can become a reality, however, the resultant reduction in drug-development costs by 75% and cuts in lead time by nine years, as reported in a recent study, are way overestimated. With sustained FDA oversight (not altogether a bad thing), the need for continuous quality reviews, and the diminishing supply of successful drug candidates the tendency will be higher development costs and a deceleration of the number of drugs to market. Judy Klein, B.S., MBA Manager, Clinical Services Procurement Amgen

An article from

Supply Chain

Filed Under:

Manufacturing