VIEW on Wholesale Pricing Models In an exclusive to PharmaVOICE, Adam J. Fein, Ph.D., Founder and President of Pembroke Consulting Inc., a firm that helps senior executives of wholesale distribution, manufacturing, and B2B technology companies build and sustain market leadership, discusses why pharmaceutical manufacturers must learn how to use fee structures to leverage their influence and encourage true supply-chain partnerships. Fee-for-service payments should be designed to reward concrete actions that build a company’s brands, lower supply-chain costs, speed new product launches, and take into account any other actions required relevant to a company’s business objectives. The shift to a fee-for-service pricing model in pharmaceutical wholesaling is slowly but steadily gaining momentum. The wholesale channel will not change overnight, but as evolution occurs the contribution of wholesalers to sales, marketing, customer service, and logistics requirements also can change. According to Adam J. Fein, Ph.D., founder and president of Pembroke Consulting Inc., pharmaceutical manufacturers must learn how to use fee structures to leverage their influence and encourage true supply-chain partnerships. Otherwise, they risk missing an opportunity to think strategically about these new compensation models. “Since so much of a drug wholesaler’s gross margin comes from manufacturers, channel relationships predictably have become overly focused on negotiations regarding fees and discount rates,” he says. “Today during negotiations over fee for service, pharmaceutical manufacturers and their cost consultants are focused almost exclusively on tactical cost-avoidance questions, such as how can we measure wholesalers’ cost-to-serve for our products? What is the cost of logistics alternatives? And, what is a fair level of profit?” Dr. Fein says these questions miss the more significant strategic opportunity now open to drug manufacturers. “Based on our research and experience in other industries, channel compensation programs can represent powerful tools for motivating change and driving business results,” he says. “Fee-for-service payments should be designed to reward concrete actions that build a company’s brands, lower supply-chain costs, speed new product launches, and take any other actions required to remain relevant to a company’s business objectives.” Barriers to change For many years, pharmaceutical manufacturers have offered cash discounts and forward-buying opportunities to support the legitimate costs of wholesale distribution for their products. Relatively high product price inflation rates for ethical pharmaceuticals allowed wholesalers to earn a 15% to 20% return on inventory. “Forward buying was profitable enough to hide the fundamental flaws of this system,” Dr. Fein says. “Trade discounts, rebates, and payment terms are all indirect and blunt tools that add little value to the healthcare system and warp incentives to lower supply-chain costs. For example, the pressure to meet Wall Street expectations encouraged some manufacturing executives to ‘rent’ market share at the end of every quarter.” According to Dr. Fein, the adoption of inventory management agreements (IMAs) over the past few years altered this dynamic. In a basic IMA, the wholesaler agrees to reduce or eliminate forward buying of a manufacturer’s products in return for a fee structure or payment from the manufacturer to offset the wholesaler’s economic losses from the discontinuation of forward buying. “Essentially, manufacturers have been paying their wholesalers not to speculate with inventory, although the transition away from inventory profits has shrunk wholesaler profits more quickly than most analysts or company executives anticipated,” he says. But most IMAs are still based on a percentage of sales rather than transaction or fee-based compensation. The transparency and integrity of the drug supply chain is reduced by any wholesaler-compensation approach linked to manufacturer price increases. According to Dr. Fein, existing accounting standards and reporting requirements allow manufacturers to bury the wholesale distribution costs for their products and wholesalers to hide the profit contribution of vendor payments. “Many manufacturers will resist this transparency, as we estimate that fully accounting for distribution costs would reduce operating profits for pharmaceutical manufacturers by billions of dollars,” he says. paying for performance Fee-for-service is a channel compensation approach by which customers or suppliers pay directly for the channel’s services rather than having those services bundled in gross margin and unseen discounts. Manufacturers gain customized support and accountability, while distributors earn fees commensurate with their effort, costs, and results. By separating product costs from service costs, fee-for-service pricing provides a more accountable way of measuring and compensating for the value activities in the supply chain. “Since wholesalers are likely to play an ongoing and important role in the healthcare supply chain, pharmaceutical manufacturers must learn how to use fee structures to leverage their influence and encourage true supply-chain partnerships,” Dr. Fein says. “Pharmaceutical company executives should begin by describing the specific, prioritized objectives and requirements for their wholesalers today and in the future. Wholesaler compensation should be directly linked to the specific results or activities that influence a company’s preferred outcomes.” For example, representative outcomes include service levels to retail customers, transparency to customer sales and inventory, control over secondary market activities, price integrity across channels, or reduction of the manufacturer’s internal supply-chain costs. “In other words, executives should focus on the outcomes that their company seeks rather than trying to measure the cost structure of a third-party wholesale supplier,” he says. “The key is to mix the carrot of additional rewards with the stick of margin loss to motivate change and create new wholesaler management tools.” Dr. Fein outlines some best practices from other industries that could be applied to healthcare: • Shift incremental compensation to require a minimum performance (for basic compensation) and exceptional results (for incremental results). • Add numerous small penalties for service-level performance below requirements (late delivery, incomplete order, incorrect price, etc.). • Force wholesalers to drive behavior down into their organization with incentives and penalties targeted at lower-level and functional managers. • Incorporate customer-level metrics of service performance for the largest and most significant retail accounts. • Require the population of two-way report cards, analyst/management attention, and periodic review and benchmarking. Developing a more efficient channel system Superior channel compensation programs offer all wholesalers the same choice; either step up to deliver new results or operate at a lower level of investment and commitment. Distributors that opt in incur higher costs, but also have access to incremental incentives. Channel members that opt out make a decision to focus on different end-customer value offerings. “Over time, the end result of this self-selection is a more efficient channel system that is better aligned with a company’s business objectives,” Dr. Fein says. Manufacturers also can use fee-for-service programs to encourage movement toward longer-term channel strategy objectives. “For example, manufacturers can add partnership incentives to encourage certain wholesalers to become ‘supply-chain superstars,’ ” he says. “These incremental incentives would be associated with systems investments, supply-chain management training for a wholesaler’s employees, management education, and above all, working toward customer transaction visibility, in other words ship-to-customer orders, not restocking.” The supply-chain superstar label will help reward wholesalers, and retailers, that are hyper-focused on the customer and patient. Dr. Fein adds that this strategy could also address the negative public perceptions of the pharmaceutical industry’s supply-chain inefficiencies and gaps. Another option is to offer customer-service development funds to wholesalers that can propose and develop innovations targeted at improving demand-driven supply. Any wholesaler can submit a business plan for developing a supply chain-related customer for-fee service that leverages the combined competencies of the wholesaler and manufacturer. In other industries, he says, manufacturers retain the right to approve plans and require wholesalers to cofund mutually beneficial programs. “All of these approaches and tools require drug manufacturers to put aside adversarial relationships and focus on ensuring sales to downstream customers and patients,” Dr. Fein says. “The goal should be to shift costs to the most efficient point in the supply chain and become more sophisticated in managing wholesalers.” For more information or to contact Dr. Fein, visit pembrokeconsulting.com. PharmaVoice welcomes comments about this article. E-mail us at [email protected]. Many manufacturers will resist transparency, as we estimate that fully accounting for distribution costs would reduce operating profits for pharmaceutical manufacturers by billions of dollars.

An article from

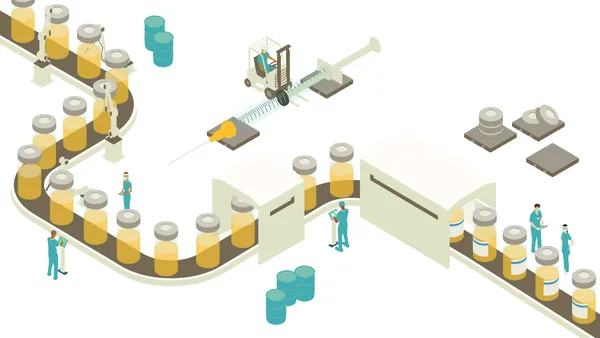

Fee-For-Service: Getting What You Pay For

Filed Under:

Manufacturing