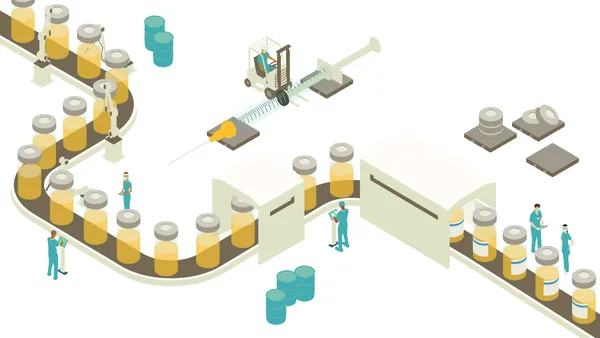

Ensuring trial-supply management is an integral part of overall clinical-trials management and manufacturing can bring efficiency to development and save companies time and money. Discussions about increasing efficiency and reducing time lines in clinical development often focus on patient and investigator recruitment for trials. But a critical area that doesn’t get as much attention is clinical-trial supplies management. “The people working on the protocols are so focused on getting everything in place to start the study on time that it works out well if we can partner with them to handle the complexity of the clinical-trial materials supply chain,” says Steve Jacobs, associate director, Spring House Clinical Supplies Unit, at J&J Pharmaceutical Research & Development. Christopher Holt, VP of healthcare at UPS Supply Chain Solutions Consulting Services, agrees. “Typically clinical-trial managers for pharmaceutical companies don’t have a background in supply-chain management,” he says. “Their job is to manage the scientific aspects of the clinical trial, making sure the drug is being tested, the data are properly tracked, and that the results are properly interpreted. Evaluating how the drug moves through the supply chain is often an afterthought.” Mr. Holt says pharmaceutical companies have to think of the clinical-development process as being a supply-chain operation just like everything else they do. “Pharma companies need to start thinking and acting more like high-tech companies or consumer-products companies,” he says. “Efficiency should start with the clinical trial and that should permeate through the entire organization. We say start with excellence up front, and it will make life a lot easier downstream.” Pharmaceutical companies shouldn’t completely separate clinical-trial supply management from other manufacturing challenges, says Roddy Martin, VP of research at AMR Research. “Efficiently managing clinical-trial supplies is based on the effective management of the entire clinical-trial management process, the supply network, and the manufacturing product supply network,” he says. “This is an end-to-end strategic process. Reducing the time and improving efficiency of clinical trials has massive implications for taking products to market. Companies have to bring clinical-trial supplies into their mainstream manufacturing and IT strategies.” Anita Dopkosky, R.Ph., VP of marketing and sales at McKesson BioServices, a unit of McKesson Corp., says pharmaceutical companies should plan trial-supply logistics well in advance. “Project managers shouldn’t let clinical supplies be the last part of the process planned,” she says. “A clinical-supplies expert should help write the clinical-supplies plan in the protocol. For example, for one trial we were doing in Africa, at the client’s request, we packaged the patient kits in cardboard boxes. But what our client didn’t consider was the high humidity and the lack of air conditioning at the site. The cardboard boxes almost collapsed. Everything was fine, but the kits had to be repackaged into moisture resistant containers.” Most mid- to large-size pharmaceutical companies, such as Johnson & Johnson, have a department dedicated to the needs of clinical-trial supply management. “The benefit of having a clinical supply-chain unit that focuses specifically on packaging, labeling, and distribution is its laser-like focus,” Mr. Jacobs says. “In this way, those working on the protocol can organize the trial, focus on recruitment, collect the data, and make sure all regulatory requirements are in place. Then they can work with a unit such as ours, which will coordinate, organize, and establish what the clinical-supplies needs are, kit configuration, shipping, and so on.” Jon Hess, a senior analyst at Cutting Edge Information, says formalizing communications between the two groups can go a long way toward making trial-supply management more efficient. “It also is very important that these two groups understand each other’s limitations,” he says. “We often hear from trial-supply groups that their clinical development counterparts change deadlines or set unrealistic goals.” Forecasting Materials Companies are confronted with a very difficult forecasting problem: determining how much of a trial drug to produce and to send to sites. Too much drug sent to sites can result in waste and not enough drug could put the protocol or the trial at risk. Predicting the need for a scarce resource in quantities that can widely vary can create major bottlenecks, says Joel Hoffman, VP, practice management, at Intrasphere Technologies Inc. “Large quantities of very expensive drugs can be potentially wasted,” Mr. Hoffman says. “Typically, companies forecast studies and require supplies at the same time they identify project programs for the coming year. The actual studies that are approved may be very different from the initial forecast, and actual studies started will be different from the final forecast list. From our perspective, we have not witnessed companies implementing cost-effective tools that track actual supplies against forecast or simulation or other predictive models to save costs and resources.” Three years ago, sites had drug overages of about 75%, says Stacy Gletzakos, director, e-services, at Perceptive Informatics Inc., a division of Parexel International Corp. “Today, in some cases, we are witnessing overages in the 10% range,” she says. “While this may seem like a positive in terms of cutting down on waste, what it inherently implies is that there may not be a sufficient drug supply. Based on the factors that we take into consideration — such as the number of countries involved, the number of sites, the number of depots, and so on — 10% is no longer an optimal percentage to keep a blinded trial blinded. The end result is that the trial may be in jeopardy.” Covance Inc. makes use of historical run rates as one way to help it project materials the company needs, says Jim Harkness, senior director of clinical trial support services, at Covance. “We have at our disposal an inventory management system that evaluates a couple of different factors to make sure that we have supplies in time for patient visits,” he says. “The system, which integrates our kit production with the inventory system managed through our clinical-trials database, also takes into account future patient visits to determine what kits will be needed.” Mr. Harkness says another issue is that sponsors often don’t know which sites are going to be heavy or light patient enrollers or when they will actually see their first patients. “The challenge is to find the right balance,” he says. “Because products have a defined shelf life, companies don’t want to send out too much product that results in waste.” One way to help monitor and track an inventory of clinical-trial supplies is an interactive voice response system, says Eddie Montoya, director, service development, interactive voice response services unit, at Covance. “IVRS combines the patient-enrollment information directly from sites into one database allowing sponsors to know exactly what’s happening at all of their sites around the world,” he says. “The IVRS uses the telephone as a data-entry mechanism, and the data come straight from the doctors or hospitals around the world. As soon as patients come into the system, the IVR system can be used to randomize those patients. Not only do we know when they are going to come back because of a given visit schedule, we also know what they are going to receive when they come. The system can accommodate any statistical randomization schema. Additionally, the system, based on expiration dates of the drug units, makes sure that products nearing expiration are shipped and assigned first.” Mr. Montoya says sites welcome having a system that helps manage their drug supplies for trials. “Before IVR, sites would have to communicate with either the pharmaceutical company or the distribution center to request that more drug be sent,” he says. “A site’s primary business is treating patients not managing inventory. The site would often wait until it ran out of drug before calling to get more. This could take days and sometimes weeks, depending on where the supply was coming from. There was a potential for sites to lose patients because they had to wait for drugs.” Perceptive Informatics also has developed a proprietary IVR system to help with inventory tracking of trial materials. “Any time a medication kit or a study drug is sent out to a site it is tracked,” Ms. Gletzakos says. “Likewise, if a drug is damaged or replaced this information also is tracked. Any time a medication is touched, whether it is at the distributor, at the site, or at a depot, we know about it. All of this information is real time and can be reported back.” According to Mr. Hoffman, the challenge for companies is to ensure that the data are updated and then integrated into the system so that the information can be used to support decision making. “Companies know what trials are ongoing, what supplies have been made available, the capacity — both in-house and outsourced — for additional supplies, the amount actually used, and the amounts of supplies expected,” Mr. Hoffman says. “Over time, this information can be used to improve forecasts.” For the past three years, McKesson also has been working on a new inventory management system and is now preparing to migrate smaller clients to its new system, Ms. Dopkosky says. “There isn’t a lot of off-the-shelf software available for clinical supply inventory management,” she says. “McKesson BioServices built In-Trak, a fully validated system to be able to track everything we do and give clients online access to their inventory and shipping.” Mr. Jacobs says the J&JPRD CSU is in the process of developing a new supply chain tracking and scheduling system. It is a proprietary system being developed with SAP, IBM, and Deloitte & Touche. He expects the new system to be operational by the beginning of 2006. “The system we’re moving toward, among other innovations, involves electronic batch records,” he says. “Ultimately all three of the global clinical-supply unit sites will be working from it. We have to improve the integration of all the data. For example, the requirements for labels in different countries throughout the world change constantly. To make sure we’re on track and that we are following all the regulations we work with regulatory affairs. Right now we provide regulatory affairs with a PDF file of the label for review. Eventually we would like to have a system where regulatory affairs could go online and take a look at the labels and make recommendations on the spot. This would make things much easier.” Supplies in Global Trials Getting supplies to sites outside the United States presents many challenges, from labeling issues to import/export regulations. “In many countries, there are regulations that prohibit the use of medications that do not have the appropriate labeling,” Ms. Gletzakos says. “We often recommend multilingual labels. This can minimize drug waste and avoid the need to repackage for distribution in different countries.” As part of the new Clinical Trial Directive, European regulations require a product specification file be submitted, Mr. Jacobs says. This file includes data about what is known about the products that are being sent into that country, including information about comparator products. “There is no way to get all of the comparator product information needed for a product spec file,” he says. “We are now forced to find comparators in the European Union, which is slightly challenging. We have found that some of the comparators are not manufactured in Europe and even some of the dosage strengths manufactured in the United States are not the same in the European Union.” In July 2003, the European Union issued Annex 13, which is intended to make sure that investigational medicinal products are produced in accordance with the principles of good manufacturing practice. It also is intended to ensure that there is consistency between batches of the same investigational medicinal product used in clinical trials and that changes during the development of an investigational medicinal product are adequately documented and justified. “This legislation requires that when we ship a drug to the EU, it must first go through a qualified person before it can go to the clinical site,” Ms. Dopkosky says. “We just can’t ship to a site. This is a whole layer that has been added.” McKesson BioServices, she says, has formed a strategic alliance with DHP, a company in Wales, to act in a qualifying role. Mr. Jacobs says Annex 13 also requires expiration dates on all drugs, especially for clinical-trial supplies. “This is not required in the United States because the regulations are clear,” he says. “During an entire clinical trial, from first patient in to last patient out, there will be on-going stability studies, which regulators can look at. Annex 13 creates a challenge, especially with a young product because stability is not well known. We are labeling bunches of blister cards throughout the world and have to send out new and updated expiration dating labels for all those blisters in countries where Annex 13 is enforced. This is a huge use of resources and manpower.” Mr. Montoya says some countries in Europe are still trying to interpret these rules. “We may not see the full impact of this particular law until the government agencies in the various countries complete their review process,” he says. Shipping and Storage Industry experts say materials requiring cold temperature storage can create an additional inventory challenge. “More and more there are special requirements for handling certain drugs, particularly drugs for oncology trials,” Ms. Gletzakos says. The shipping and validation of products that require cold storage are important considerations as well. “It is quite easy in the United States to send a package that’s cold supply chain,” Mr. Jacobs says. “It leaves the dock today, and it’s at the site tomorrow. But shipping internationally is another story. For example, a product leaving a U.S. dock might not arrive at a site in Japan for four to seven days. The shipment has to go through customs and regulatory groups, and if there are any issues it will just be held. Keeping a cold-chain product cold while it gets to where it needs to go is not as easy as it sounds.” Another area of concern for the industry is in the area of child-resistant packaging as required by the Consumer Product Safety Commission (CPSC). “Many in the clinical-supply industry believed we were exempt from having to make blister packages child-resistant,” Ms. Dopkosky says. “The CPSC, however, has said we have to comply. So any blister package has to be child-resistant, even if the package is for a clinical trial for seniors with arthritis. This is a huge challenge.” In May 2000, the CPSC gave the industry two years to comply; all investigational products intended for at-home use must be child-resistant or data must be provided to the CPSC that show the drug dispensed will not cause serious harm to children. PharmaVoice welcomes comments about this article. E-mail us at [email protected]. Experts on this topic Anita Dopkosky, R.ph. VP, Marketing and Sales, McKesson BioServices, Rockville, Md.; McKesson BioServices, a unit of McKesson Corp., is a leader in clinical supply and biological specimen management. For more information, visit mckessonbio.com Stacy Gletzakos. Director, E-Services, Perceptive Informatics Inc., Boston; Perceptive Informatics, a division of Parexel International Corp., develops and offers a portfolio of technology-based products and services that facilitate clinical drug development. For more information, visit parexel.com. Jim Harkness. VP, Operations and Clinical Trial Management Systems, Central Labs Unit, Covance Inc., Indianapolis; Covance is one of the world’s largest and most comprehensive drug-development services companies. For more information, visit covance.com. Jon Hess. Senior Analyst, Cutting Edge Information, Durham, N.C.; Cutting Edge Information provides research and consulting to the pharmaceutical industry and the financial services industry. For more information, visit cuttingedgeinfo.com. Joel Hoffman. VP, Practice Management, Intrasphere Technologies Inc., New York; Intrasphere Technologies is a technology consulting firm with a core focus on the life-sciences industry. For more information, visit intrasphere.com. Christopher Holt. VP, UPS Supply Chain Solutions Consulting Services, Alpharetta, Ga.; UPS Supply Chain Solutions has resources to manage every aspect of global supply chains, from transportation management to logistics and distribution to customs brokerage and international trade services. For more information, visit ups-scs.com. Steve Jacobs. Associate Director, Clinical Supplies Unit, J&J Pharmaceutical Research & Development, Spring House, Pa.; Johnson & Johnson Pharmaceutical Research & Development probes the frontiers of science in pursuit of new drugs, based on discrete molecular targets, in the areas of vascular research, neuroscience, metabolic diseases, immunology, reproductive health, oncology, virology, antimicrobials, and inflammation. For more information, visit jnjpharmarnd.com. Roddy Martin. VP, Research, AMR Research, Boston; AMR Research provides research and actionable advice for executives tasked with delivering enhanced business process performance and cost savings with the aid of technology. For more information, visit amrresearch.com. Eddie Montoya. Director, Service Development, Interactive Voice Response Services Unit, Covance Inc., Princeton, N.J.; Covance is one of the world’s largest and most comprehensive drug-development services companies. For more information, visit covance.com. Christopher Holt Because companies are consumed by regulatory issues, they may not focus on how efficient their supply chain is. But I think companies should focus on both. Jim Harkness A challenge is to provide sites with the right balance of product. Products have a defined shelf life; if too much is sent there’s a lot of waste and a lot of resupply that has to take place. Eddie Montoya IVRS is probably the single most important tool for managing the supply of drugs to trial sites. IVRS can combine the actual patient enrollment from sites across the world into one database, which can help companies more accurately manage inventories. Anita Dopkosky A clinical-supplies expert should help write the clinical-supplies plan in the protocol. Project managers shouldn’t let clinical supplies be the last part of the process planned. Steve Jacobs The benefit of having a clinical supply-chain unit that focuses specifically on packaging, labeling, and distribution is its laser-like focus. In this way, those working on the protocol can work with a unit such as ours, which will coordinate, organize, and establish what the clinical-supplies needs are, kit configuration, shipping, and so on. Jon Hess As trials are becoming more common in parts of Western Europe, Central and Eastern Europe, China, and elsewhere, companies have to translate the labels for the trial drugs into different languages. This has become a big challenge for trial managers.

An article from