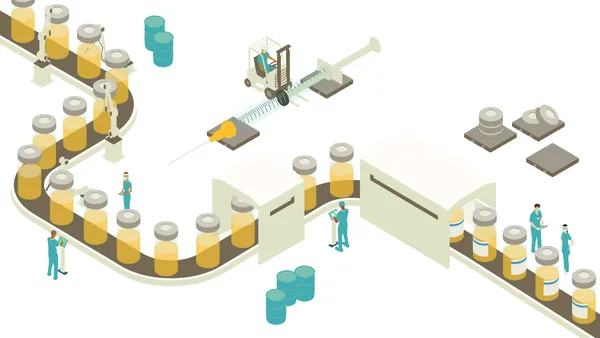

Distribution support systems More sophisticated products mean new and more elaborate distribution-support systems are needed to move the manufacturer closer to the patient. In an exclusive to PharmaVOICE, David Hileman, VP of RxCrossroads, discusses the changing dynamics of distribution channels and shortening the distance between manufacturer and patient. T wenty-five years ago, distribution channels for pharmaceutical products were straightforward. Products moved directly from the manufacturer’s warehouse to the end user – a direct retail pharmacy account – or through a wholesale distributor. As time has marched on, manufacturers and products require much more complex and elaborate distribution support networks. The varying numbers of distribution channels available to manufacturers today grant them the power to alter the strategic placement of product, as external pressure points mandate. Driving Factors Influencing Change The traditional distribution avenues include selling the product directly to the end users – large retail pharmacy chains – or through pharmacy wholesalers, such as Cardinal Health, McKesson, or AmeriSource Bergen. These channels allow the manufacturer to place the product into a large, national distribution system and immediately recognize the sale of the product. What is lacking for the manufacturer is the ability to control the movement and levels of inventory. “As products have become more complex and the manufacturing process increasingly cumbersome – yields from biotech manufacturing processes are as low as 70% – the need to manage inventory levels has become paramount,” says David Hileman, VP of RxCrossroads. “Limited product availability, due to a combination of complicated production processes and market demand, higher value products, and smaller patient populations, has produced the need for manufacturers to have tighter management over inventory levels.” Evolution of Distribution Channels According to Mr. Hileman, during the early 1990s, as the wholesale drug industry was going through consolidation, wholesale drug players established alternative methods – specialty distributors – to distribute higher cost medications coming to the market. Cardinal Health established National Specialty Services, Bergen-Brunswig launched ASD, and Bindley-Western started Priority Healthcare. “These three subsidiaries represented new distribution options for manufacturers,” he says. “There was a focus on nationwide distribution of expensive therapies, through a single location providing national distribution support, rather than multiple warehouse locations with regional capabilities. Specialty distributors grew out of a need to provide pharmaceutical and biotech products directly to physician’s offices.” These organizations feature telemarketing capabilities that directly reach prescribers and effectively offer an alternative avenue to “touch” the physician. In recent years, an explosion of what might be called specialty pharmacies also has occurred, Mr. Hileman says. “As with the specialty distributors, specialty pharmacies provide support focused on specific therapeutic areas,” he continues. “The services offered tend to be either physician- or patient-centric, depending on where the medication is administered.” Specialty pharmacies offer support services such as compliance and persistency programs and after-hours clinical personnel and caregiver networks. Frequently, they provide educational support material available either through direct mail or their custom Websites. Products are delivered through mail service to the address designated by the patient, providing nationwide distribution coverage from a single location. “Managed therapies can include cystic fibrosis, hepatitis, HIV/AIDS, rheumatoid arthritis, and oncology drugs,” he says. Mr. Hileman says players in the specialty pharmacy market include large retail chains such as CVS (CVS/ProCare), Eckerd’s Specialty Pharmacy Services, and Walgreens (Walgreens Specialty Pharmacy Services). Pharmacy benefit management companies such as Express Scripts (Specialty Distribution Services) and Caremark also offer these services. Additionally, there are examples of specialty distributors that have acquired specialty pharmacies, such as Priority Healthcare’s acquisition of Freedom Drug. Manufacturers recognize the need to control capital expenditures and focus on areas in which they excel. The distribution management of their products is an area where partnering with an outside vendor to manage this process potentially has multiple benefits. “Almost in parallel with the development of specialty distributors and pharmacies, third-party logistics companies emerged, focusing solely on healthcare products,” Mr. Hileman says. “These organizations offer the manufacturer the ability to, from one single location, fill nearly every channel of distribution. Third-party organizations can act as a manufacturer’s warehouse, shipping product to wholesalers and retail outlets; as a specialty distributor, shipping product directly to physicians’ offices and clinics; and potentially, as a pharmacy, shipping patient-specific orders directly to patients.” New Strategies Various external factors and product parameters impact how products move through the maze of distribution. Through the combination of the traditional and “newer” alternative distribution channels, manufacturers are able to develop a customized approach to product distribution. “The curtailed availability of product, particularly for either life-threatening or chronic conditions, due to higher demands for the product or lower productivity from manufacturing, requires manufacturers to make adjustments on the distribution of the product,” Mr. Hileman says. Illustrating this point, Mr. Hileman points to the launch of Enbrel by Immunex, now part of Amgen, and Wyeth. “Faced with market demand outpacing production, the brand team was challenged to provide fair and equitable distribution of the product in a chronic-care market,” he says. “Additionally, as an expensive self-injectable medication, certain reimbursement challenges had to be solved.” The Enbrel group developed a program granting enrolled patients a guaranteed flow of product. With the program serving as a gatekeeper, product was managed through a third-party logistics company. Each qualified patient was provided with a unique program ID number. When Enbrel was needed for the patient, for example a refill prescription, the pharmacist processing the prescription contacted his or her wholesaler to place the order, providing the patient ID number to the wholesaler. Product was drop shipped from the third-party logistics company directly to the dispensing pharmacy, thus eliminating the placement of precious inventory into a large-scale distribution network. Recently, the Enbrel team increased production capacity through an additional manufacturing site, thus eliminating the need for the patient-management program. “Another example of a manufacturer faced with the need to control product distribution because of inventory levels was Bayer for its product Prolastin,” Mr. Hileman says. Before September 2000, Prolastin, which is indicated to treat alpha 1 antitrypsin deficiency, was available through specialty distributors and specialty pharmacies. “The availability of this lifesaving medication became a critical issue,” Mr. Hileman says. “In September 2000, Bayer elected to refocus distribution of the product through a single source, the Bayer Direct Program, managed by Express Scripts. The new program provided one pharmacy as a single source for the product for all patients. This program bypassed the wholesale and distribution markets, taking the product directly from the manufacturing facility to the dispensing pharmacy, thus bringing the patient even closer to the manufacturer.” Patient Population/Cost of Therapy With the enactment of the Orphan Drug Act more than 25 years ago, new medications have been developed to treat diseases affecting small numbers of patients. Medications such as Tracleer, a dual endothelin receptor antagonist to treat pulmonary arterial hypertension and manufactured by Actelion Pharmaceuticals, and Zemaira, an alpha 1 proteinase inhibitor, manufactured by Aventis Behring, are controlled by a limited distribution network consisting of a select number of specialty distributors and specialty pharmacies. “For manufacturers that need to manage a risk element of their products, a limited or controlled-distribution program is a critical component,” Mr. Hileman says. “Celgene’s Thalomid and Orphan Medical’s Xyrem are two such products. The manufacturers have established distribution programs driving products directly to either the physician’s office or to the patient. Physicians requesting these products enroll their patients into a product-support program. Through the support program the risk element is monitored, the patient is evaluated, and the product is either allowed or denied. Once the determination has been made that the risk element does not exist for a particular case, the product is shipped from the manufacturer to the patient’s physician office for administration. The manufacturer is now reaching the end user, the patient’s physician, directly.” The Road to the Future “History shows us that pharmaceutical and biotech manufacturers generally place limitations on distribution channels only when and if required by either product, patient, or disease-state challenges,” Mr. Hileman says. “But, as the number of sophisticated therapies continues to increase so will the mechanisms through which these products reach the end users. Manufacturers will apply the distribution network appropriate to support both the patients and the strategic initiatives of the manufacturer.”F PharmaVoice welcomes comments about this article. E-mail us at [email protected]. VIEW on distribution channels Faced with market demand outpacing production, the brand-management team was challenged to provide fair and equitable distribution of the product in a chronic-care market. As products have become more complex and the manufacturing process increasingly cumbersome – yields from biotech manufacturing processes are as low as 70% – the need to manage inventory levels has become paramount. VIEW on distribution channels

An article from

Distribution Support Systems

Filed Under:

Manufacturing