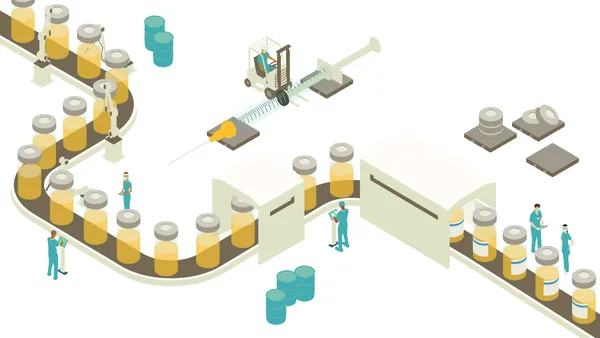

A Corporate Citizen BY kim ribbink Integral to darlene ryan’s mission as founder, president, and CEO of PharmaFab is positioning the company as a corporate partner with integrity, as well as being responsible to the community. Darlene Ryan believes it is the duty and responsibility of business people to be involved in their community. She feels so strongly, in fact, about giving back to the community that she encourages PharmaFab employees to become involved as well. Beyond its mission as a contract manufacturer, Ms. Ryan says one of the early goals for the company, and one that remains central to its makeup, is being a business based on integrity, respect, and partnership. PharmaFab was founded in November 1994 by Ms. Ryan, along with her brother, Bruce Montgomery, and her father, Kenneth Montgomery. She has spent a great deal of time on the board of directors for the Girl Scouts. As vice chair for Junior Achievement, she and members of PharmaFab’s senior-management team teach classes to children in their community. “Involvement in the community has been a good thing for PharmaFab because people want to work for a company that is a good citizen,” she says. Ms. Ryan says her role in the company is to be a visible spokesperson within the industry and community. It seems probable that Ms. Ryan has always been destined to lead a company. From early in her studies and throughout her career she has demonstrated the resourcefulness, analytical thinking, and enthusiasm required of a CEO. At first glance, her decision to establish a contract pharmaceutical manufacturing company seems a less than obvious choice given her background in public accounting. But on closer examination, this proved to be a perfect fit. She founded the company with her brother, a mechanical engineer, and her father, a pharmaceutical chemist who had been in the pharmaceutical manufacturing business throughout his career. “This was the business I grew up in,” Ms. Ryan says. “With each of our competencies, we figured if any three people could make this type of business succeed, it was us. We had experience in the business and financial areas, and in engineering and manufacturing. Plus my dad had many contacts in the industry.” PharmaFab is a contract manufacturer of solid dose and liquid formulations of branded and generic pharmaceuticals. Though less than 10 years old, the company has received widespread recognition for its rapid growth, its community involvement, and its dedicated leader. Ms. Ryan has maintained her vision through personal adversity, including the death of her father, to ensure PharmaFab achieves economic success and respect. Finding the Right Note Ms. Ryan attended DePauw University in Indiana, initially as a clarinet major. Her father, recognizing that this was not where her talents lay, advised her to choose another path, and she switched to mathematics and German. Mathematics was a natural choice for someone who gravitated toward the sciences, but her second major was, she says, never intentional. For years, Ms. Ryan had written to a pen pal in Germany, who even today is one of her closest friends. “Fluency in German opened doors for me professionally,” she says. “This got me noticed as a young employee at Arthur Andersen and it fueled my interest in other cultures and in having an international career.” It was in college that Ms. Ryan’s leadership talents were first recognized. She applied for, and was granted, the George F. Baker Scholarship, which is given to students who the trustees believe will be future business leaders. The scholarship is given to about 200 students nationwide each year based on interviews with the board of trustees. Not only did the scholarship pay for Ms. Ryan’s last two years of college, but also for a MBA program at a school of her choice. Ms. Ryan joined Arthur Andersen immediately after graduating from DePauw in December 1975. While at Arthur Andersen, Ms. Ryan earned her MBA at the University of Chicago. Thereafter, she settled into a career at the accounting firm, working for more than 18 years as an international tax specialist. In 1987, she was made partner. Ms. Ryan says Arthur Andersen taught her the crucial leadership skills that made it possible for her to lead a successful company. “One of the first things I learned was how to delegate; when you’re in public accounting that’s an important lesson,” she says. “Another critical lesson I learned is to never just join an organization or association, but lead. PharmaFab became a member of the Generic Pharmaceutical Association when it was formed a few years ago, and it was natural for me to suggest to the board that the organization needed a finance committee and that I needed to chair it. I’ve been the secretary/treasurer of the GPhA for the last four years.” Perhaps most significantly, Ms. Ryan says, she learned that business requires an emphasis on integrity. “Despite Arthur Andersen’s recent association with corporate scandals, all of us at the company believed in integrity; it was the foundation for everything we did,” she says. “This integrity is equally important in the pharmaceutical industry. Both accounting and pharmaceutical company reputations are based on trust. We have to gain people’s trust and live up to that responsibility.” Moving from accounting to pharmaceutical manufacturing appeared to be a giant leap to some of Ms. Ryan’s former colleagues at Arthur Andersen. But as she points out, her entire career has been about understanding regulatory issues, a particularly critical issue in the pharmaceutical industry. “People tend to think the two are very different industries,” she comments. “As a tax partner, I dealt with regulations every day. I read and figured out what regulations meant, and I consulted with attorneys when I needed more clarification. I was familiar with how the federal government works with regard to tax regulation, and FDA regulations aren’t that much different from tax regulations.” A Family Affair For Ms. Ryan and her two founding partners, the basis for starting the company was to develop new and simpler ways to manufacture pharmaceuticals. “As a mechanical engineer, my brother always looks for ways to simplify things, and make processes repeatable,” she explains. PharmaFab’s customers are the major generic pharmaceutical companies and distributors, and smaller, branded companies. The company manufacturers extended-release and immediate-release tablets and capsules, as well as a variety of liquid products, including formulations for cough/cold and pain-relief products. (See box on page 61 for more information.) What sets PharmaFab apart from its competitors, according to its leader, is a business model that establishes a close partnership with customers. “We do a great deal of formulation work, and we advise clients on their product strategies,” Ms. Ryan says. “We suggest ways that could help them gain approval faster. We also suggest ways that could simplify manufacturing down the track. We get involved in brainstorming sessions around product strategy, and that’s not something we charge for. We offer clients a different level of partnership.” Both the company and Ms. Ryan have enjoyed some thrilling times, often around the successful launch of a company’s product. Achieving Milestones According to Ms. Ryan, a high point for the company was implementing its own granulation batch technology. PharmaFab had a signed agreement with Rhodia Inc. to license the technology for the granulation process, along with a long-term supply agreement for the raw material. The two companies worked together in 2001, as PharmaFab built a section of its facility and transferred the technology. “This was an ambitious project for our small company to do with a huge multibillion dollar multinational company,” Ms. Ryan says. “PharmaFab had been purchasing materials from Rhodia for a year or so but we wanted to granulate our own materials, both to save money and to better control our supply. “Within six months, we were up and running, but we were all holding our breath the day we turned on the new machine,” she says. Ms. Ryan also has had to contend with some very difficult personal circumstances. “Losing my Dad to cancer was, of course, a real low,” Ms. Ryan says. “Another low was buying out my brother’s half of the company. I’m a team player; I’m not good at being a lone wolf, and after my brother left the business I had to adjust to being the one who was left, at least until I could build a supporting management team.” Knowing how critical it was for the future of the company that she maintain her focus helped Ms. Ryan to deal with those losses, as well as other difficulties. She attributes that focus to watching her father cope with his illness. The family discovered soon after PharmaFab was incorporated that Kenneth Montgomery had cancer and that his chances of making it beyond two months were slim. “We easily could have abandoned the idea at that point,” Ms. Ryan notes. “But we recognized that the company was his legacy to our family. In the end, my father lived two years and a day after the diagnosis and I maintain that the business helped him persevere so long.” Ms. Ryan says this was an important lesson for her. “When I have trouble outside the office, the business helps me keep sane. I’ve built a company where I love to come to work and a lot of other people do too.” The Capsule for Growth When PharmaFab started out it had nothing on the books. In its first year of operation it had sales of $30,000. By 2003, sales had grown to $25.5 million, and this year Ms. Ryan predicts sales of around $40 million. In October 1999, PharmaFab expanded into a new production facility in Grand Prairie, Texas. And its employee base has grown to 140 full-time employees. The company continues to capitalize on opportunities by developing techniques that give its clients an edge. “Over the last year or so, we’ve applied for patents on time-release technologies/processes used in the manufacturing to ensure we remain innovative,” Ms. Ryan explains. “Many of our customers manufacture older drugs, which leaves them open to competition from a generic company. Through patented technologies to reformulate their products, we can help our customers keep their products from being challenged.” Both the company and Ms. Ryan have received widespread attention, which has helped PharmaFab to gain traction with customers. Though still a young company, PharmaFab has been included for three consecutive years in the Inc 500 list of America’s fastest-growing private companies. Ms. Ryan also has received recognition for her entrepreneurial spirit. In 2001 and 2002, she was a finalist for the Manufacturing Entrepreneur of the Year, Southwest Region, by Ernst & Young. In 2003, she was honored by Ernst & Young as the Entrepreneur of the Year for the Southwest Region in the Life Sciences. And, in May 2004, Ms. Ryan was one of 21 women worldwide to be honored by The Leading Women Entrepreneurs of the World. Ultimately, what keeps Ms. Ryan and her staff motivated is the industry that they serve. “I was in Washington, D.C., on September 11, 2001, just a block from where the attack happened,” she explains. “When I got back to Texas, I felt it was important to contribute in some way, to do something. I spoke with my staff and we did what many people did – donated money and blood. But I also realized that we contribute everyday by virtue of what we do. We play a part in helping to keep people well.” F PharmaVoice welcomes comments about this article. E-mail us at [email protected]. DARLENE Ryan It is the duty and responsibility of business people to be involved in their community. People want to work for a company that is a good citizen. I encourage PharmaFab employees to become involved as well. public endeavors What is your management style? I hire really smart people and give them the resources and guidance to do what they’re best at. That tends to foster independent minded, driven people. I don’t hire “yes” people. I recognize that I’m the one who has to make the decisions, but if I don’t hire independent resourceful people, the company will end up just being me. It’s healthy to have many different viewpoints. You have consistently lobbied on Capitol Hill for less government regulation and affordable pharmaceuticals for patients. What changes do you believe need to be made? The FDA gave a license to one company to manufacture single-ingredient guaifenesin, which required us to stop manufacturing that product for our customers. This actually benefited the company financially because it was our least profitable product. But creating a monopoly for the product hurt consumers. The drug went from costing 10 cents a tablet to an average of 70 cents a tablet. The reason behind the FDA move was that the agency wants companies to seek approvals for the older drugs, and it decided a monopoly would create an incentive for companies to seek approval for older drugs. But there are thousands of older drugs that have never posed a safety risk. Together with a few others in the industry, we have proposed to Congress a prescription drug monograph for older drugs. This would lay out parameters, such as dosage ranges, or time release, or a combination of the two; and if those drugs were within those ranges a company would not be required to get preapproval for marketing those drugs or those combinations. Requiring companies to get approval for these older, proven drugs is costly, and those costs get passed on to the consumer without any benefit to the public health. why do you think community service is so important? I’ve spent a lot of time on the board of directors for the Girl Scouts, and I’m vice chair for Junior Achievement. In fact, my entire management team and I teach Junior Achievement classes. In addition to donating our time, we donate money. I recently started a charities committee made up of nonmanagement PharmaFab employees who meet several times a year to decide on where our corporate charitable contributions will be spent. I lead them in making those decisions. It’s my way of training others to give back to the community. And it’s a way to involve the whole company in making those decisions, because any money PharmaFab gives to the community comes from the efforts of everyone. It’s their money, and they should have some involvement in deciding where that money goes. I also believe that it’s good leadership training for my people. What, in your opinion, are the biggest challenges facing pharmaceutical manufacturing? The biggest challenges are making pharmaceuticals safely with the highest quality possible and at the lowest cost possible. The challenge is to save money for consumers, while keeping drugs safe, but still making enough money to stay in business. In pharmaceutical manufacturing, we’re caught in the center of that dichotomy of cost and safety. That’s the challenge and that’s why we’re seeing debates about branded products versus generic products and how both fit into the formula. In an exclusive interview with PharmaVOICE, Darlene Ryan, president and CEO of PharmaFab, talks about the way she leads, her community and lobbying efforts, and the challenges that face the industry. A Born Leader DARLENE RYAN – resume 1994 – Present. President, CEO, and Cofounder, PharmaFab, Grand Prairie, Texas 1987 – 1994. Andersen Worldwide Partner, Arthur Andersen, San Diego (1991 – 1993), Los Angeles (1986 – 1991) 1975 – 1987. Member of the firmwide international tax specialty team, Arthur Andersen, Denver (1982 – 1986), Chicago (1976 – 1982) Educational Background 1978. MBA, University of Chicago. George F. Baker Scholar 1976. B A. with majors in mathematics and German, DePauw University, Greencastle, Ind. Phi Beta Kappa, Summa Cum Laude honors Professional Affiliations Certified Public Accountant: Member of the American Institute of CPAs since 1987; Member of the Texas Society of CPAs since 1994; Member of the Education Committee of the Colorado Society for CPAs, 1991 – 1993 Generic Pharmaceutical Association: Member of the Board of Directors and Secretary/Treasurer since April 2002. Chair of the Finance Committee, 2000 to 2002 committee of 200: Member since September 2002 of nationwide group of women entrepreneurs Executive Women’s Roundtable: Member since September 2002 of this group of Dallas area entrepreneurs, organized by the Greater Dallas Chamber of Commerce Chief Executives Network: Member since January 2001 of the nationwide CEO peer group inc eagles: Member since October 2001 of the nationwide CEO peer group formed by Inc Magazine fort worth women’s business center advisory council: Advisory Council member since 2001 Awards and Honors 2004. Recipient of The Leading Women Entrepreneurs of the World 2003. Ernst & Young Entrepreneur of the Year Award in Life Sciences for the Southwest Region 2003. Tarrant County Healthcare Hero 2002. Texas Women of Excellence Award for contributions to the community 2001. Regional Working Woman Entrepreneurial Excellence Award for Overcoming Obstacles A Look at PharmaFab PharmaFab has expertise in manufacturing all types of prescription pharmaceuticals, including products used to treat pain and cough/cold symptoms. Its products are currently in three dosage forms: tablets, capsules, and liquids. Additionally, PharmaFab develops ANDAs for its customers. The company aims to provide solutions to customers’ needs by developing new technologies and applying for patents when that is what is needed to formulate the combinations that make sense for the product its customers want to bring to market. The company’s manufacturing and formulation capabilities include: Encapsulation: With the latest Bosch equipment on site and several patents pending on technologies of their own, PharmaFab encapsulates combinations of beads, powders, and/or mini-tablets in a variety of sustained-release or immediate-release formats. Tablets: Blenders of various sizes and types and on-site fluid bed granulation with patent-pending technologies allow PharmaFab to formulate and compress tablets of various shapes, sizes, and formulations. Immediate- or sustained-release formulations are available. Liquids: PharmaFab manufactures both solutions and suspensions for its customers, in combinations of immediate- and sustained-release formats, using some of its own patent-pending technologies. Fluency in German opened doors for me professionally. my language skills were noticed while at Arthur Andersen and it fueled my interest in other cultures and in having an international career.

An article from

Darlene Ryan: A Corporate Citizen

Filed Under:

Manufacturing